Mobile Robotic Tiling

Applying robotic technology to building construction work to increase productivity, reliability, quality, and safety

Bringing the Productivity of Robots to Construction

There is high potential to apply robotic processes in the construction industry since the productivity of construction work is notoriously low compared to other manufacturing industries. In particular, onsite work is still heavily dependent on manual labour.

The situation in Singapore and its construction industry seems particularly suited for the application of robotic solutions for construction work, and can act as a catalyst for future application. While the scenario for high population growth over the next decades demands a high degree of unbroken building activity, the country suffers from the lack of skilled workers. Moreover, tiling is the predominant surface treatment in Singapore and the high-rise typology with repetitive floor plans makes automation feasible.

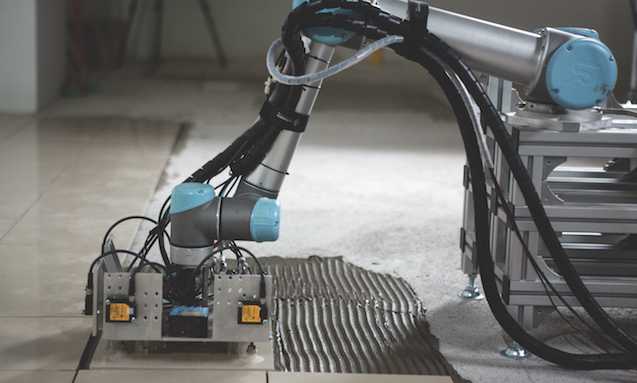

Robotic systems, combined with intelligent control software, offer the dexterity and flexibility needed for construction work and can be a feasible solution to increase productivity. These systems combine the benefits of automation, such as a constant controlled quality for increased durability and sustainability, and an overall facilitation of building production, with the adaptability and flexibility needed for construction work.

Tiling work, in particular, is suited for robotic automation. It is a well-defined subdomain of construction with clear interfaces that can easily be singled out. Furthermore, it is a repetitive task and features no complex joinery. Automating this process is expected to benefit the construction industry as a whole as the robotic co-worker can safely work alongside humans without employing additional security measures. It is to be integrated to the existing construction workflow, lowering the entry barrier for adopting new technologies in the building industry.

The expected outcome of the project is to realise an automated tiling process which demonstrates the feasibility of applying a mobile robotic system for planning and executing onsite tiling work. An essential benchmark for the project is its ability to compete against manually executed work in terms of quality, time, and costs. The result will be evaluated against current construction work in Singapore.